In 2019, Huawei launched the AI Boost Smart I-V Curve Diagnosis 3.0, integrating Artificial Intelligence (AI) technology in the field of solar operation and maintenance (O&M) for the first time. The solution uses smart photovoltaic (PV) inverters to scan PV strings to obtain the relationship (I-V curve) between the output voltage and output current. The smart PV management system performs big data-based analysis on the I-V curve of PV modules, applies AI smart diagnosis algorithms, identifies faulty strings accurately, and outputs a diagnosis report. Through AI self-learning, the solution is accumulating I-V experience and optimizing fault models, transferring O&M of solar PV into the AI era.

What Problems Can Smart I-V Curve Diagnosis 3.0 Solve?

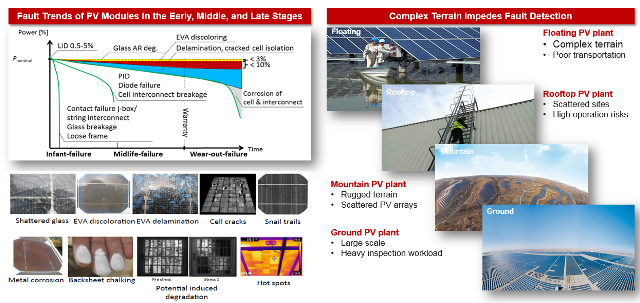

It is fully proved that PV module faults are the key factor that affecting the energy yield of PV plants. PV module faults at early, middle, and late stages differ greatly. Manual inspection and traditional supervisory control and data acquisition (SCADA) cannot accurately locate the root cause of the faults. Traditional I-V detection is offline detection that requires site visits with devices carried. A 100 Mega Watt (MW) PV plant, for example, has tens of thousands PV modules and covers an area equivalent to 300 football fields. As a result, not all PV modules can be scanned. Moreover, generating reports manually is error-prone and time-consuming. Increasing PV application scenarios, complex terrain, as well as the advent of new types of PV modules such as bifacial PV modules all impede manual detection and raise the costs.

Huawei Smart I-V Curve Diagnosis 3.0 changes the traditional manual sampling detection. The system performs full detection on all PV modules. It takes only 15 minutes to scan a 100 MW PV plant and automatically generate a detection report covering 14 types of faults. The solution applies to a wide variety of PV scenarios, such as large-scale ground, distributed, and residential PV plants. The detection is completed online, sparing the personnel of site visits. This greatly improves the O&M efficiency of PV plants in the entire life cycle and reduces the O&M cost.

Compared with monofacial PV modules, bifacial ones, affected by weather and ground conditions, suffer the mismatch effect more. Due to the uneven irradiation on the rear side of bifacial PV modules and ground reflected diffuse, the accuracy requirement of the I-V detection is higher. Besides, the incurred current mismatch should not be simply considered as faults. Through AI self-learning, Smart I-V Diagnosis 3.0 further adapts with bifacial PV modules, improves the recognition accuracy of bifacial modules’ model, and accurately identifies mismatches caused by shading and PV module faults.

Application of Smart I-V Curve Diagnosis

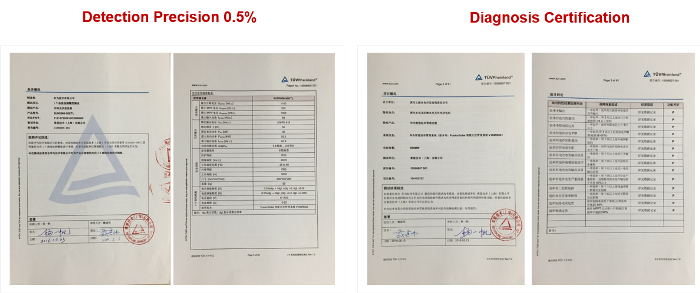

Recognized and highly appraised by customers worldwide, Smart I-V Diagnosis has been deployed globally in large-scale ground, distributed industrial and commercial rooftop, residential rooftop, mountain, floating, solar-agricultural, and solar-fishery PV plants with a scale of over 5 GW by now. It is certified onsite by TÜV Rheinland that Smart I-V Diagnosis has the data precision up to 0.5%. A 100 MW smart PV plant in Golmud, Qinghai witnessed the 15-minute detection for all PV strings with 100% accuracy.

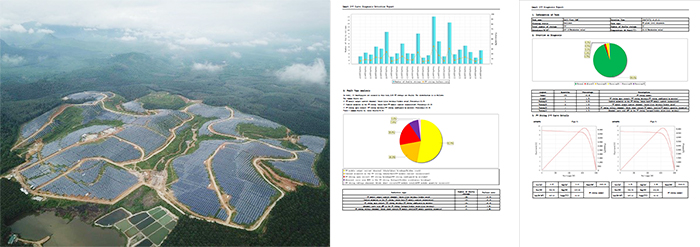

In an undulating ground PV plant in Malaysia, Smart I-V Curve Diagnosis was used to scan 9,496 PV strings with 1,149 ones detected as faulty. The fault rate was 12.1%. Based on the Smart I-V Curve Diagnosis report, O&M personnel had a detailed understanding of the health status of each PV array, which facilitated targeted site maintenance. If all the faults are fixed, the power generation of this plant will increase by more than 1.5%.

AI technology has promoted industrial upgrading and transformation. The renewable energy industry has ushered in a rapid development period of digital transformation. In the field of PV plant O&M, Huawei will take advantage of its innovative technology and extensive experience to greatly improve O&M efficiency, reduce O&M costs, and improve the operating efficiency of the entire life cycle of PV plants.