With applications in distributed energy storage, electric vehicles, co-located solar and storage, and more, the demand for lithium-ion batteries is on the rise. With this is also the demand for making improvements to performance, safety, and energy density to rapidly scale the technology.

In pursuit of these improvements, the National Renewable Energy Laboratory (NREL) and the University of Ulm developed an unprecedented computer model that can represent the architecture of a Li-ion electrode particle with sub-particle grain detail. The findings were published in npj Computational Materials.

“This breakthrough allows NREL to perform single-particle characterization for Li-ion cells,” said Donal Finegan, NREL staff scientist and project lead. “We know that the morphology and orientation of grains within the cell can greatly affect the rate performance and life of the electrode. With this model, we can evaluate the physical conditions that lead to improved batteries.”

Initial use of the model has already led to better understanding of how physical conditions affect how lithium travels through the electrode and around the crystals. The sub-particle details will be used to inform research on extreme fast charging can be performed without accelerated degradation of the battery.

Similar breakthroughs are being made in the development and advancement of solar PV cells. A recent collaboration between MIT and Google led to the development of a high-resolution solar cell computer model.

A chief challenge in Li-ion research is that improvements must be made at the microscopic level. There are no presently-existing methods for measuring sub-particle reactions in Li-ions, so the model offers a first look into their properties. The limits of microscopic imaging have been pushed against for years, said NREL, so the model offers a new way to understand the material.

“Microscopy techniques always require a trade-off,” Finegan said. “For example, tools that measure particle morphology overlook vital information about the chemical properties or crystal structure due to systematic limitations. We’ve realized there is no way to get all of the information we need in one place.”

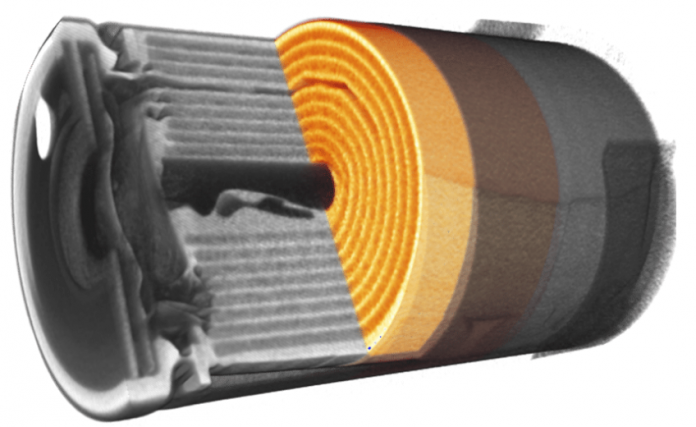

The fusion of two of NREL’s advanced technologies allowed for the creation of the model. X-ray nano-computed tomography captured the outer shape of the particles. Focused-ion beam electron backscatter diffraction captured the internal grain distribution and sub-particle information. Together, a model of the li-ion particle could be created.

“Merging data streams is not a trivial task,” said Finegan. “Microscopy itself is highly specialized, and these tools each output data in their own way. To generate this model, our team was tasked with not only characterizing the information from each data source, but then translating it to an entirely new format.”

NREL said future research will employ machine learning to speed the data acquisition and analysis process, leading to faster insights in the future.