Over the last few years, drones have become an industry standard for inspecting solar PV plants. Thermographic and visual spectrum drone inspections have replaced manual module inspections, improving accuracy, efficiency and speed.

Above is a global solar PV inspection and data analytics company advancing the deployment and operation of solar PV plants through aerial data and analytics. The company is partnered with the University of Essex in England to enhance the research and development of autonomous drone technology for utility-scale solar. Earlier this year they embarked on a new project named ‘Follow PV’ to develop cutting-edge drone robotics for the solar industry, funded by Innovate UK.

“It’s clear that robotics is playing an increasingly important role in the solar industry, and it’s exciting that Above is continuing to lead the agenda”, said Will Hitchcock, CEO and founder of Above.

The project unites experts in solar, robotics, artificial intelligence (AI), sensors and embedded systems to develop a spatially aware drone that can rapidly process and make in-flight corrections using artificial intelligence and sensing technology. This will enable the drone to better capture the condition of PV modules in greater detail by flying closer to the solar panel surface.

Jinya Su, University of Essex’s principal investigator and a lecturer in AI and Robotics in the School of Computer Science and Electronic Engineering, said: “UAVs, equipped with dedicated sensors (cameras, LIDAR) for environmental perception, would be the future for industrial inspections. This is particularly the case when UAVs are combined with autonomous flying functions (to be developed in this project) and AI for data analysis. Solar industry would significantly benefit from these technologies considering its large scale and also the time/labour/cost involved in the conventional human manual inspection.”

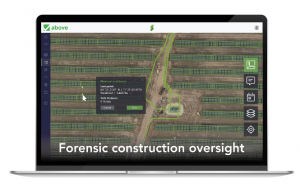

Recently drone technologies are being used to manage solar plant construction projects on a global scale. Above has developed a digital method of monitoring the construction of large-scale solar projects, increasing the quality of work and reduce operational risk throughout the process.

At the heart of the solution is Above’s cloud-based platform, SolarGain. Designed especially for solar, SolarGain works to unify all solar plant testing and inspection data within one collaborative and sharable environment.

“Our software was conceived to document the birth of an energy asset since its inception,” Hitchcock told PV Tech. “It is offered to our clients during construction operations with the aim of de-risking their projects.”

The company uses drones equipped with sensors and high-definition cameras to capture an exceptionally accurate and detailed image of the solar plant construction site.

The solar plant construction plans are ingested into the platform and aligned with the image of the site. The platform generates a colour coded overlay that provides insight into the progress of construction. Each coloured area represents the completion status of components such as modules, inverters and cable runs.

The result is a fully interactive digital model of the construction site.

Users can assess the construction progress, track progress against milestones, record design deviations and share rich project information with stakeholders. During construction, the site is constantly changing and so detecting and recording these changes is a necessity.

Users can assess the construction progress, track progress against milestones, record design deviations and share rich project information with stakeholders. During construction, the site is constantly changing and so detecting and recording these changes is a necessity.

Detailed drone scans are carried out throughout the project often aligning with key milestones. Each time new data is collected and processed into an orthomosaic image, it appears as a new layer within the site model.

“This comprehensive collection of data replaces static spreadsheets and PDF reports, thus providing more clarity and precision in one cloud platform” Hitchcock added.

The solution enables users to generate as-built documentation during construction, creating a permanent digital record for the future. This digital record provides oversight to inform future major remedial works, technical due diligence, and asset transfer.

Once a solar plant project reaches the commissioning stage, its digital twin is ready to use in the SolarGain platform. The platform provides a digital representation of all the site components electrically and geospatially mapped. The software supports bulk data uploads of everything from factory flash tests to serial numbers. The platform can also integrate with SCADA monitoring to create an even richer data environment.

“Investors and EPC contractors can visualize all historical data and the different construction stages in an interactive environment and for different sections of the plant,” Hitchcock said. The recent innovation enables companies to capture all commissioning testing and inspection data and add it to the exact component within the plant model.

Above’s mobile inspection tool, EyeSite, helps ease this time-consuming process by enabling instant data uploads such as serial numbers and visual inspections into the digital twin. For instance, a visual inspection can be recorded using EyeSite, uploaded to the digital twin, and then transformed into an EPC-ready punch list. With more data than ever, digital twins provide a permanent record for the future and a smooth transition into O&M.