The Fraunhofer Institute for Solar Energy Systems ISE has recently published a study in which the CO2 footprint of six monocrystalline silicon photovoltaic modules manufactured in China, Germany and the European Union was calculated.

The scientists considered the CO2 emissions that arise during the manufacture, transport and operation of the solar modules and found that the products with the lowest carbon footprint are those produced in Europe. “With PV modules manufactured in the EU, I save 40 percent in CO2 emissions compared to modules imported from China,” said Holger Neuhaus, head of Module Technology at Fraunhofer ISE, noting that the carbon footprint related not only to the savings in emissions caused by the transport, but also and primarily to the energy mix of the respective countries. On the other hand, the emissions that result from the transport of the solar modules from China to Europe only account for around 3% of total emissions, while the energy required for the module manufacturing has a share of between 50 and 63%.

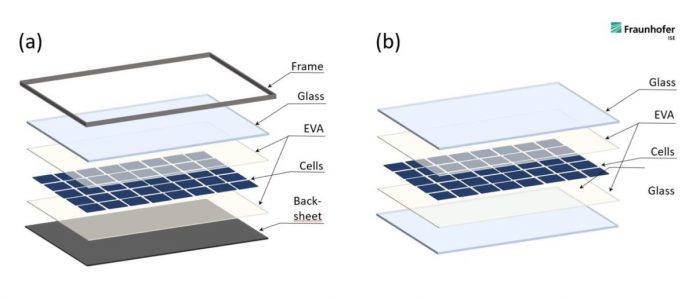

For glass-glass solar modules manufactured in the EU, there are 420 kilograms of CO2 equivalents per kW of power, according to the Fraunhofer ISE’s calculations. For glass-backsheet solar modules from the EU, there are 480 kilograms of CO2 equivalents per kW of power. When manufacturing in Germany, the researchers determined values of 520 and 580 kilograms of CO2 equivalents per kW of power.

When solar modules are produced in China, by contrast, 750 or kilograms of CO2 equivalents are produced per kW of power. The better values for glass-glass solar modules are based on the fact that they do not require an aluminum frame. Its production is very energy-intensive. In addition, glass-glass solar modules have a longer service life and less degradation than their glass-film counterparts, which also has a positive effect on the CO2 footprint. As to the kWh generated, the frameless glass-glass module causes 22 to 27 percent fewer CO2 emissions than the glass-backsheet module, the researchers explained.

For its study, Fraunhofer ISE used the new production data that was collected in collaboration with the industry. “This is the real news. Compared to life cycle analyses based on older data sets that are still used today, the study showed that the carbon footprint of PV modules has improved by about 80 percent in recent years,” Neuhasu stated. “This is due to improvements in the silicon yield, the manufacturing processes of module efficiency and the CO2 intensity of power generation.”

Institute director Andreas Bett said the results confirmed the need for establishing a photovoltaic production chain in Europe. “Due to the significantly lower CO2 emissions during production and the further strong increase in demand for more climate-friendly PV modules worldwide, it is now a matter of establishing the PV production chain in Europe quickly and with a great deal of commitment.”

In recent years, large parts of PV production have been relocated from Europe to Asia, mainly to China. In 2019, China produced 68% of polysilicon, 96% of all wafers, 76% of all solar cells and 71% of solar modules worldwide.