Researchers from the University of Rome Tor Vergata, Germany’s Fraunhofer Institute for Organic Electronics and the South Colombian University, in Colombia, have developed a flexible perovskite solar cell for indoor applications said to function under illumination of 100-500 lux.

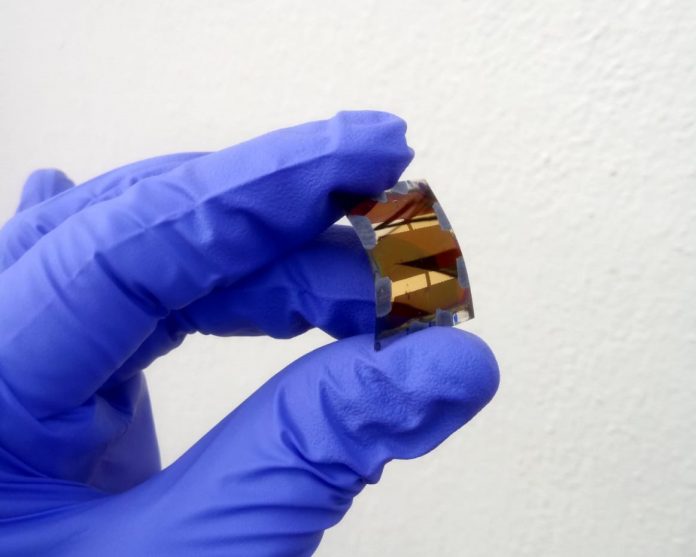

The 100 micrometer-thick device was manufactured using roll-to-roll sputtering with an indium tin-oxide coating on ultra-thin flexible glass with transmittance of more than 80%, sheet resistance of 13 ohms-per-square and bendability surpassing 1,600 bending procedures at 20.5mm curvature.

The device incorporates a mesoporous scaffold over compact layers of stannic oxide which, according to the researchers, is the decisive factor in reaching cell conversion efficiencies of 20.6% and 22.6%, under 200 and 400 lux LED illumination, respectively.

Those efficiency levels are the highest recorded for a flexible PV cell designed for indoor use, according to the device’s developers, and are also 60-90% better than the best-performing perovskite PV cells on flexible substrates. “Specific powers in Watts delivered per gram of weight (W/g) are 40-55% higher than their counterparts on plastic polyethylene terephthalate (Pet) films and an order of magnitude greater than those on rigid glass,” said the Euro-Colombian group.

Costs

Research co-author Thomas Brown said the estimated manufacturing cost for producing tens of thousands of square meters of fully encapsulated perovskite solar cells on flexible glass per year would be around $110/m². “Considering that the cell area required to provide energy to low-power electronic devices such as wireless sensors depends on illuminance levels found indoors; how power-hungry the device is; and how often it senses and communicates; the associated costs of manufacturing the PV component – excluding cutting, packaging and integration – would, thus, be from under $0.10 to the $1 range,” Brown told pv magazine.

The researcher said the industrial scale manufacture of flexible perovskite solar cells on Pet substrates costs around $34/m², excluding special encapsulation costs. “Swapping the cost of flexible plastic substrates, of around $6/m², with the estimated cost for ultra-thin glass substrates of approximately $40/m², the manufacturing cost for perovskite solar cells on flexible glass would be $68/m²,” he added.

Adding $10 for simple plastic sheet encapsulation and $40 for another sheet of flexible glass – required for applications which require the longest lifetimes – the cost of a fully encapsulated PV cell on ultra-thin flexible glass for indoor use would be $78-108/m².

Large area

The researchers added, bringing their device to mass production would involve increasing the cell area from 1cm2 to around 10cm2, potentially reducing the efficiency figure to around 18% – still very high for flexible perovskite cells.

“The roll-to-roll fabrication of devices on flexible glass can not only be implemented for the indium tin-oxide, but also for all other layers in the future in order to lower the fabrication costs, improve the production yield of flexible perovskite solar cells and allow the application of such devices as a first choice as indoor light harvesters for low-power electronics, sensor nodes and … internet of things [devices],” the group stated.

The cell is described in the paper Perovskite Photovoltaics on Roll-To-Roll Coated Ultra-thin Glass as Flexible High-Efficiency Indoor Power-Generators, published in Cell Reports Physical Science and on the ScienceDirect website.