As renewable energy sources become more prevalent nowadays, solar energy systems are being widely adopted by businesses and homeowners. It is an excellent way to generate electricity cleanly and efficiently, but it also comes with its own set of unique challenges. One such challenge is the risk of fire, which can be caused by various factors such as overloading, loose connections, or a faulty inverter. In recent news, there have been reports of a fire accident at a photovoltaic (PV) system.

On October 16th, 2022, a pharmaceutical factory in western Sydney, Australia, suffered significant property damage and millions of dollars in equipment loss due to a fire caused by solar panels on the factory’s roof.

In July 2022, a solar power plant in Sas van Gent, Zeeland province, Netherlands caught fire due to sustained high temperatures, and the fire spread over an area of about 5000 square meters. The cause of the fire was unknown.

In June 2022, a fire broke out on the roof of an industrial building in Prince George’s County, United States, and thick smoke filled the area. Local firefighters believe the fire was likely caused by photovoltaic components.

According to statistics, more than 80% of fires are caused by faults on the DC side of PV systems. In PV systems, due to the stacking of component voltages, a series of component circuits often have a direct current high voltage of about 600V to 1000V. When cable connections age, connectors malfunction, models do not match, or when two conductors with opposite polarity are very close together and the insulation between the two wires fails, it is very likely to produce a direct current arc under the action of high voltage, which can cause an open flame and lead to a fire. Therefore, it can be seen that the arc sparks caused by high DC voltage are the “culprit” of photovoltaic fires.

In order to prevent fire risks in PV systems, in addition to regulating system design and installation, and strictly controlling product quality, certain technology and equipment can also be used to greatly reduce the probability of fires.

This is where microinverters come in. As the world’s pioneer of high-power microinverters, TSUN has always attached great importance to safety issues in the solar industry.

Microinverters from TSUN adopt a low-voltage parallel connection method, ensuring that DC generally stays lower than 60V on the roof, while string inverters can go up to 600-1000V. It effectively reducing the risk of high voltage DC and improving the safety of photovoltaic power generation systems. Rapid shutdown is also already implemented in every inverter, making it easy to shut off in case of emergency.

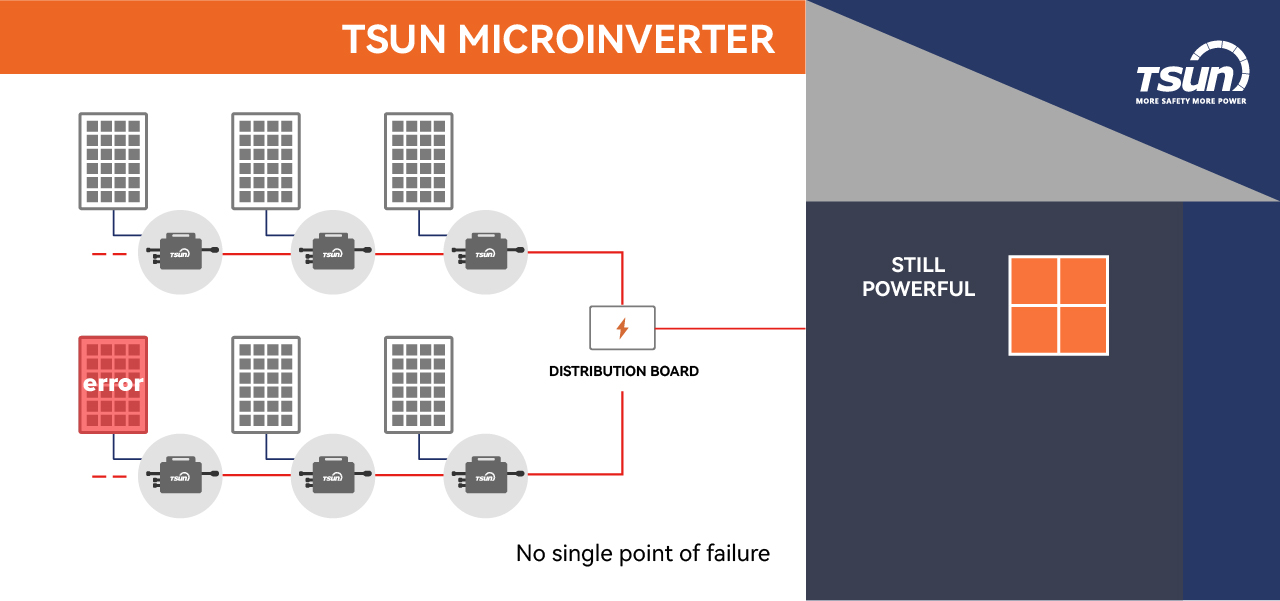

In addition, TSUN’s microinverters come with a monitoring system that provides real-time data on the performance of each panel in the system. This allows for early detection of any issues, such as a faulty panel or loose connections, that could lead to a fire. With this information, the problem can be addressed before it causes any damage.

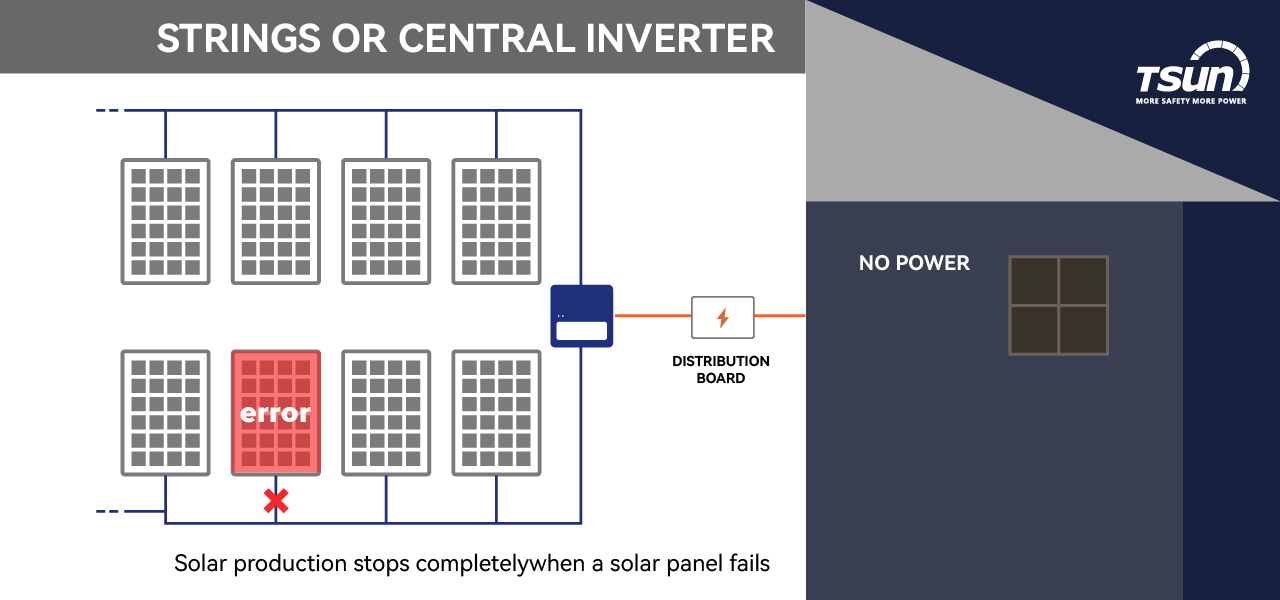

Because string inverters connect panels in a series, if one goes down or produces less energy, every other panel in the series is also affected. This is especially an issue if partial shading of your panels is happening throughout the day as the entire system will only perform as well as the lowest producing panel.

On the other hand, microinverters from TSUN do not experience this same issue because they connect in parallel, which ensures that all the panels are working independently at their highest efficiency.

With the continuous development of the distributed market, TSUN will continue to uphold the concept of “More safety, More power” and push the safe development of photovoltaics to a new level. At that time, more owners can freely enjoy truly safe and clean green energy.