Scientists from Nanyang Technological University in Singapore and Université Grenoble Alpes in France have combined a slot-die coating technique with gas quenching and substrate heating to fabricate a perovskite solar cell with an active area of over 0.09 cm2 and a power conversion efficiency of 18%.

Gas quenching is used primarily in connection with hardening in vacuum furnaces and slot-die coating is a process already used in various industries. Ink is pushed through a narrow slot as it moves across a substrate to form a continuous film. Substrate heating is commonly applied in the pulsed laser deposition (PLD) process.

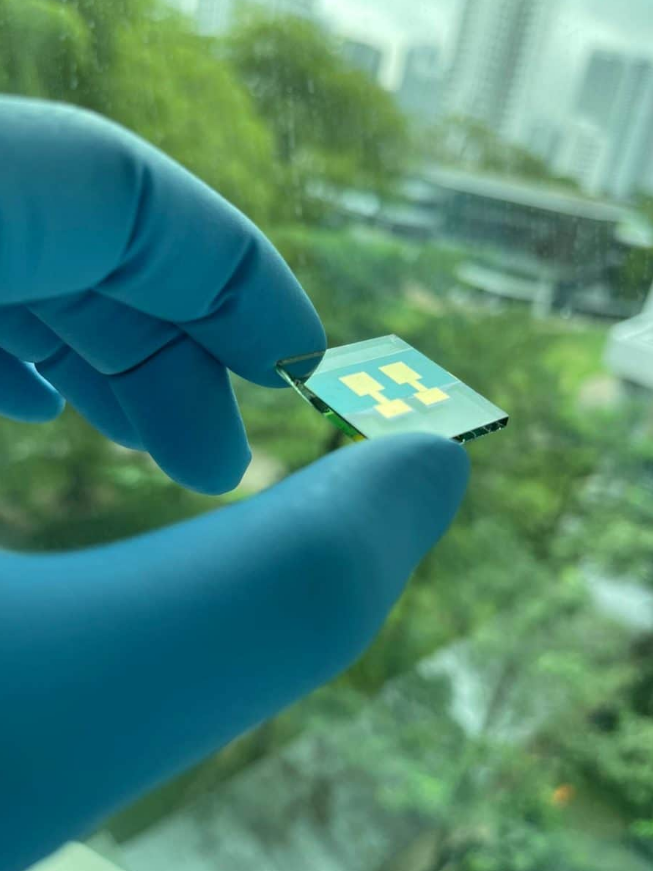

These techniques, which the researchers described as a combined “synergistic crystallization strategy,” was used to coat a methylammonium-free perovskite film with a thickness of around 500 nm over a fluorine-doped tin oxide (FTO) substrate of 10 × 10 cm2 without the use of solvents or additives.

The perovskite precursor ink was prepared in a nitrogen-filled glovebox by mixing lead(II) iodide (PbI2), formamidinium iodide (FAI), lead(II) bromide (PbBr2), and cesium iodide (CsI).

“The solution was kept at 40 C under stirring overnight and transferred to the slot-die tubing system the next day,” the scientists said. “For the perovskite module fabrication, P2 scribing was performed with a CO2 laser with adjusted power to remove specifically the perovskite and the hole transport layers and a manual P3 step was performed by Kapton tape masking.”

The cell has an ‘n-i-p’ layout and is composed of the fluorine-doped tin oxide (FTO) substrate, a Tin(IV) oxide (SnO2) layer, the perovskite film, a layer made of gold (Au). It also has a spiro-OMeTAD hole-blocking layer, which is typically used as a hole transport material for solid-state dye solar cells and perovskite devices.

The best performing slot-die coated solar cell showed an efficiency of 18.03%, an open-circuit voltage of 1024 mV, a fill factor of 78.6% and short-circuit current density of 22.4 mA cm−2.

“The device performance reproducibility was assessed by fabricating 30 devices from the same substrate,” the academics said, adding that their average efficiency was 16.35%.

They described the cell and the related production process in “Slot-die coated methylammonium-free perovskite solar cells with 18% efficiency,” which was recently published in Solar Energy Materials and Solar Cells.

“This work provides an insight into the processing window for perovskite meniscus coating and paves the way toward large-scale processing of MA-free perovskites,” the researchers said.