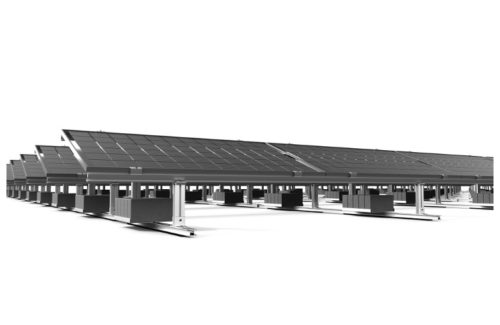

Canadian solar racking company Opsun has unveiled a new generation of rail-based bifacial solar racking for flat commercial rooftops.

Named the Sunrail SR3, this upgraded third-generation racking system now boasts fewer parts, and requires even fewer tools to install.

“Racking system failure is the most unspoken issue within the rooftop solar industry,” said Alex G.-Vanasse, VP Business Development at Opsun Systems. “Poorly engineered systems fly-off from roofs, and low-quality racking rusts and becomes unable to hold solar panels over time. All these issues are no secrets, and yet few solutions exist in the market today to resolve this at an affordable price.”

The Sunrail SR3 is an aluminum, rail-based system that meets the latest American (ASCE-7-16) and Canadian (NBCC 2015) standards. The system uses the company’s Opsun MESHTM Technology approach that creates an ultra-detailed Finite Element Analysis (FEA) mesh that is simulated with hundreds of load cases for each configuration.

Like previous generations, the Sunrail SR3 is imagined to maximize bifacial energy gains and to cause zero shading on the back side of the solar panel. In order to maximize light capture under and behind bifacial solar panels, the Opsun SR3 can be engineered at high-tilt angles (10° to 30°), and can be tailored to have a large clearance, so it stands above most roof obstacles.

The Sunrail SR3 does not need wind deflectors, which makes installation even faster, and reduces the solar panels’ operating temperature.

“Opsun leveraged two decades of solar expertise to engineer a massive weight reduction of the solid aluminum skeleton of the Sunrail SR3, without allowing for any compromise on the structural solidity,” said François Gilles-Gagnon, President of Opsun Systems. “The resulting product is a best-in-class bifacial solar panel racking that is stronger, at an affordable price point, and powered by the most advanced computer-assisted engineering process in the industry: the Opsun MESHTM Technology.”