Having proved their potential for high efficiency and low-cost manufacturing, perovskite solar cells have caught the eye of manufacturers, and already made significant progress toward commercialization and large-scale production.

There is still a lot of caution though regarding stability and the tendency to quickly lose initial performance when exposed to moisture and other conditions they would certainly face in the field. Scientists have suggested a wealth of different approaches to this issue. And while it’s not clear which of these might be picked up in industrial production, there is general consensus that the problem can be solved.

Scientists led by Brown University in the U.S. demonstrated another approach to improving perovskite solar cell stability, working with a “molecular glue” added during processing that served to dramatically improve adhesion between the light-absorbing perovskite layer and the electron transport layer. “A chain is only as strong as its weakest link, and we identified this interface as the weakest part of the whole stack, where failure is most likely,” explained Nitin Padture, who directs the Institute for Molecular and Nanoscale Innovation at Brown. “If we can strengthen that, then we can start making real improvements in reliability.”

Self-assembled monolayers

With this in mind, the group began experimenting with a group of materials called self-assembled monolayers (SAMs). “This is a large class of compounds,” Padture continued. “When you deposit these on a surface, the molecules assemble themselves in a single layer and stand up like short hairs. By using the right formulation, you can form strong bonds between these compounds and all kinds of different surfaces.”

Settling on a SAM made up of silicon and iodine atoms, and applying this to perovskite solar cells using a dip-coating process conducted at room temperature, the group was able to demonstrate an impressive effect on the cell structure. “When we introduced the SAMs to the interface, we found that it increases the fracture toughness of the interface by about 50%, meaning that any cracks that form at the interface tend not to propagate very far,” said Padture. “So in effect, the SAMs become a kind of molecular glue that holds the two layers together.”

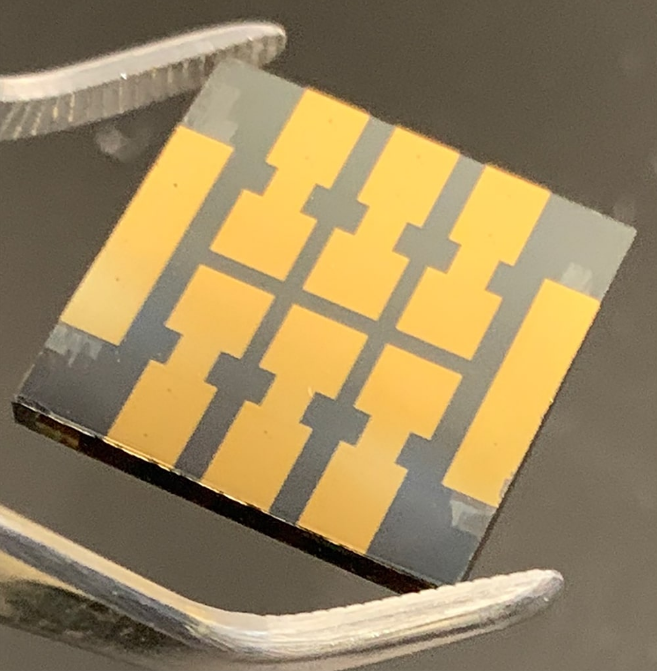

In testing, solar cells treated with the SAM achieved 21.4% efficiency and retained 80% of this after 4000 hours under 1-sun illumination and continuous maximum power point tracking. A set of control cells produced without the SAM treatment reached 20.2% efficiency and fell to 80% of the initial value after around 700 hours in the same test conditions. The experiments are described in full in the paper Interfacial toughening with self-assembled monolayers enhances perovskite solar cell reliability, published in Science.

“One of the other things we did, which people don’t normally do, is we broke open the cells after testing,” said Zhenghong Dai, a Phd student at Brown who led the research. “In the control cells without the SAMs, we saw all kinds of damage such as voids and cracks. But with the SAMs, the toughened interfaces looked really good. It was a dramatic improvement that really kind of shocked us.”

The group now plans to extend its work to strengthening the bonds between all of the other layers in the perovskite cell stacks, as well improving the mechanical strength of the individual layers themselves. And they recently received $1.5 million in funding from the U.S. Department of Energy to pursue this. “”This is the kind of research that’s required in order to make cells that are inexpensive, efficient and perform well for decades,” concluded Padture.