In early April, the Union Cabinet had approved the Ministry of New & Renewable Energy’s (MNRE) proposal for the implementation of the production-linked incentive (PLI) program for the ‘National Program on High-Efficiency Solar PV (Photovoltaic) Modules’, to achieve gigawatt-scale manufacturing with an outlay of ?45 billion (~$605 million).

The President of India finally approved the program, which aims to promote the manufacturing of high-efficiency solar PV modules in India and reduce import dependence on renewable energy.

Implementing Agency — IREDA

The PLI program will be implemented by MNRE through the Indian Renewable Energy Development Agency (IREDA) as the implementing agency. IREDA will be responsible for providing secretarial, managerial, and implementation support and carrying out other responsibilities as assigned by MNRE from time to time.

IREDA will be eligible to get 1% of the PLI amount disbursed as administrative charges annually.

IREDA will also submit a progress report to MNRE every quarter along with details of disbursement claims received for PLI, the amount disbursed, reasons for a delay in disbursement of the incentives.

IREDA will have the right to carry physical inspection of an applicant’s manufacturing units and offices through site visits. It will take the help of the National Institute of Solar Energy for determining the efficiency and temperature co-efficiency of modules. If required, MNRE may also designate National Accreditation Board for Testing and Calibration Laboratories-accredited labs, and others, for such measurement.

Selection of beneficiaries

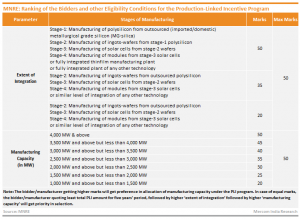

Beneficiaries of the PLI program will be selected through a transparent bidding process. Applications will be shortlisted after consideration of the following parameters:

The extent of integration: Manufacturers who propose to set up a fully integrated solar PV manufacturing plant using silicon-based technology (starting from the stage of manufacturing of polysilicon to ingot/wafer to solar cell, and module) or fully integrated thin film technology or any other technology will get preference. However, to qualify for the bid, the manufacturer will have to promise minimum integration across solar cells and modules.

Manufacturing capacity: Manufacturers who set up higher capacity plants will get preference. However, to qualify for the bid, the manufacturer will have to set up a manufacturing plant of a minimum 1 GW capacity — 1 GW each for all individual stages included in the manufacturer’s proposal.

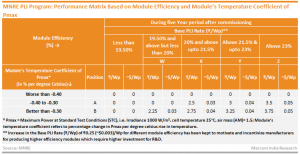

Minimum module performance: Manufacturers will also have to fulfill the minimum performance parameters. Either a minimum module efficiency of 19.50% with a temperature coefficient of Pmax better than -0.30% per degree Celsius or a minimum module efficiency of 20% with a temperature coefficient of Pmax equal to or better than – 0.40% per degree Celsius.

Several manufacturers are apprehensive that larger players will offer backward integration including cells, wafers, ingots, and modules, and a huge chunk of the PLI pie is likely to go to them, leaving little for the rest.

Ranking the bidders

Bidders who fulfill the minimum conditions as specified above will be shortlisted. Subsequently, they will be assigned marks for determining their inter se (ranking among the bidders) position as per the following selection criteria table:

Bidders eligible for PLI

The bidder can be a single company or a joint venture/consortium of more than one company. In the case of a joint venture/consortium, a partner/company will be allowed to tie up their manufacturing capacity (of any stage) with another partner/company for one bid only.

The selection of the beneficiaries will be by the bucket-filling method, keeping in view the overall PLI limit of ?45 billion (~$605 million), and the PLI requirements quoted by the bidders. The bidder getting the highest marks/inter se position will get PLI amount for five years as quoted followed by the second bidder, and so on, until the PLI amount is exhausted.

Manufacturing units that have availed any benefit under the MNRE’s tenders for solar power purchase agreements linked to PV manufacturing or special incentive package scheme (SIPS)/ modified SIPS program of the Ministry of Electronics & Information Technology will not be eligible for benefits under this program.

Manufacturing units that have imported capital goods for setting up the module manufacturing facility before the last date of bid submission will also not be eligible for participation under the PLI program.

Waiting list

A waiting list based on the marks (valid for six months from the date of selection of the manufacturers) will be maintained in case of substantial oversubscription of the bid. If the Ministry gets an additional financial outlay over and above ?45 billion (~$605 million), the waiting list will be cleared following the same bucket filling method.

Greenfield and brownfield projects

Greenfield – new solar PV module manufacturing units will be eligible for PLI. Brownfield projects will also be allowed to participate subject to the fulfillment of prescribed eligibility criteria for greenfield projects.

PLI rate for such brownfield projects will be 50% of the rate for greenfield projects.

According to the notification, brownfield projects refer to all new solar PV manufacturing capacities set up by the existing solar PV manufacturers, which share some common infrastructure facilities with the pre-existing solar PV manufacturing capacities or addition of new manufacturing lines in the existing solar PV manufacturing facilities.

Calculation of PLI

PLI will be calculated as follows:

PLI (?) to manufacturers = sales volume (Wp) × base PLI rate (?/Wp as per position in performance matrix) × tapering factor × local value addition expressed in a fraction of one.

At the time of bidding, the bidders will also have to submit the total PLI required for the five years after commissioning of the manufacturing unit. They will calculate the PLI requirement for each year based on the estimated values of the parameters in the formula above.

The actual PLI disbursed to the manufacturer depends on actual sales or the maximum capacity awarded under the PLI program, whichever is less, his actual position in the performance matrix and the actual local value addition.

However, the bidders, are not eligible for any PLI over and above the PLI requirement quoted by them for a particular year.

In case a selected manufacturer fails to meet the extent of integration or manufacturing capacity promised at the time of selection, he will not get any PLI until he overcomes these deficiencies.

If the manufacturer achieves the promised levels subsequently, he will be eligible for PLI from the next month following the month in which he achieved the promised levels of integration and capacity.

However, in such cases, the manufacturer will not be able to get PLI for full five years since five years’ PLI is counted from the scheduled date of commissioning of the plant. In case the modules manufactured by a selected manufacturer do not meet the minimum performance parameters, then he will not get any PLI for such modules.

Maximum sales (in MW) covered

Although a manufacturer can bid for any capacity (MW), the maximum capacity that can be awarded to one bidder under the PLI program is 50% of the bid capacity (capacity which he has promised to set up in his bid) or 2 GW, whichever is less.

This has been done to accommodate at least three manufacturers under the overall envelope of ?45 billion (~$605 million). PLI will be given on actual production and sales of high-efficiency modules by the selected units.

In case the annual sales (in MW) of a unit are more than the capacity (in MW) awarded, PLI will be limited to the sales (MW) equal to the capacity (MW) awarded under the PLI program.

Performance matrix

Based on module efficiency and module’s temperature coefficient of Pmax, the ‘base PLI rate’ will be determined in ?/Watt peak (?/Wp) as per the Performance Matrix Table given below:

Disbursement of PLI

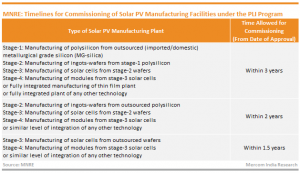

The manufacturing units approved under the program are eligible for PLI based on annual sales of high-efficiency solar PV modules for five years from commissioning or five years from the scheduled commissioning date, whichever is earlier.

In case the commissioning is delayed, the PLI period will reduce from five years by the time of such commissioning delays.

A team constituted by MNRE or IREDA will visit the manufacturing unit immediately after its commissioning to verify the promised extent of integration, manufacturing capacity, efficiency, and temperature co-efficient of modules.

The manufacturers will be asked to provide a self-declaration and a Statutory Auditor’s or Chartered or Cost Accountant’s certificate in support of claims of PLI.

The manufacturers will provide documents supporting the PLI claimed for a particular year based on sales (watt) of modules, percentage of local value addition, and PLI rate (as per the position in the performance matrix). Required documents for availing PLI will be detailed out in the tender documents.

Local Value Addition

Manufacturers will be encouraged to source their material from the domestic market. The PLI amount will increase with the increased local value addition.

Timelines for commissioning of solar PV manufacturing facilities

The time allowed for the commissioning of solar PV manufacturing units under the program is as follows.

Penalties

In case a selected manufacturer fails to meet the promised integration or capacity or minimum module performance after his selection, he will not get any PLI until he overcomes these deficiencies. If the manufacturer achieves the promised levels subsequently, he will be eligible for PLI from the next month following the month in which he achieved the promised levels. However, in such cases, the manufacturer will not be able to get PLI for the full five years.