As perovskite solar cells edge closer to commercial, a wealth of different ways to produce them is being suggested, each with its own set of advantages and disadvantages. One advantage common to most is that the active layers can be applied directly to glass or a flexible substrate at a relatively low temperature, meaning production processes can be kept fairly simple, particularly in comparison to silicon PV’s requirements for ingot growth, wafer cutting and other complex, energy intensive processes.

And when it comes to applying perovskite materials to a substrate, various types of process are suggested, from simple inkjet printing to more complex solution based processing. And now, Thailand’s Mahidol University is bringing to the table another process, this time based on precision spray coating.

The process, according to Pongsakorn Kanjanaboos of Mahidol’s School of Materials Science and Innovation, allows for the sequential deposition of stacked cell layers, including additional perovskite layers. This could allow for production of highly stable devices, and for the customization of other properties, including the color of the modules.

“With our spray coating process, the solution of the upper layer doesn’t disturb the solid film making up the first layer,” said Pongsakorn. “Endless combinations of stacked perovskite architectures with any number of layers can be designed and created with precise control of thicknesses and rates of deposition for each layer.”

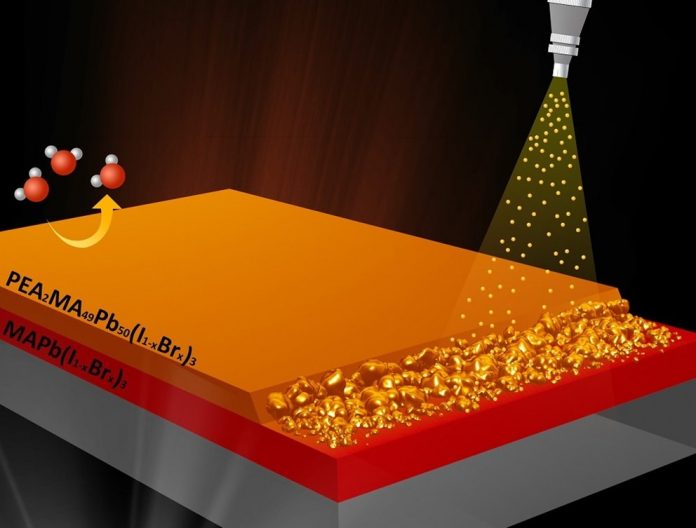

To test their process, the group fabricated a multilayered perovskite device consisting of two perovskite layers applied to a tin oxide coated glass substrate.

First methylammonium lead iodide – the most common type of perovskite used in solar cells thanks to its strong electric performance, was sprayed onto the glass. Then an additional material, known as a Ruddlesden-Popper perovskite after the scientists who first synthesized it, was sprayed on top of the first layer. This material is known to have strong stability performance, but much lower electrical performance. By combining the two layers the university hoped to demonstrate a ‘best of both’ approach.

The process and the device fabricated are described in the paper Layer-by-layer spray coating of a stacked perovskite absorber for perovskite solar cells with better performance and stability under a humid environment, published in Optical Materials Express.

The group further notes that, on top of stability, its sequential spray coating approach also allows for optimization and customization of other features, including the color of the module. Now, their work will focus on investigating other new functions made possible by the process, as well as further layer combinations to achieve the best balance between performance and stability.