Daqo New Energy’s net income attributable to shareholders fell from $38.1 million to $29.5 million in the year to the end of December, despite a strong fourth-quarter net profit of $20.1 million, up 76% from the final three months of 2018, according to its unaudited results for fiscal 2019.

However, the company expects to churn out roughly 18,000 MT to 19,000 MT of polysilicon in the first quarter of this year and 73,000 to 75,000 MT in the 12 months to the end of December 2020. That would represent a significant jump from its impressive full-year output of 41,556 MT in fiscal 2019, up 80% on the year.

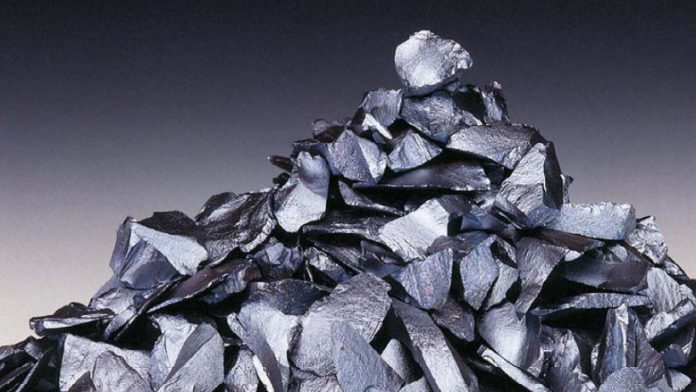

Longgen Zhang, CEO of Daqo New Energy, described 2019 as a “challenging year for China’s domestic solar PV market.” He noted that around 81% of the company’s production during the fourth quarter consisted of high-quality mono-grade polysilicon.

New factory

The company’s revenue from continuing operations reached $350 million in 2019, from just $301.6 million a year earlier. It primarily attributed the increase to higher polysilicon sales, despite lower average selling prices (ASPs). Polysilicon ASPs stood at roughly $8.77/kg in the fourth quarter, from $8.99/kg in the July-September period.

Zhang added that the company’s new Phase 4A factory is now running at full production capacity, following the completion of a 35,000 MT expansion project at the end of the third quarter.

“We quickly ramped its production up during the fourth quarter and hit full capacity in December,” Zhang explained, claiming that the project was completed months ahead of schedule.

“With the Phase 4A fully ramped up, our energy consumption, raw material utilization efficiency, and other unit costs are all trending positively.”

Daqo had a relatively strong fourth quarter, with net income jumping to $20.1 million, from just $11.4 million a year earlier. However, sliding ASPs offset a jump in sales to 13,291 MT in the three months to the end of December, from just 9,238 MT in the preceding quarter. Polysilicon production jumped from 9,437 MT in the July-September period to 16,204 MT in the fourth quarter.

Crisis response

The company recorded a net loss from discontinued operations in the fourth quarter of $0.3 million, following the third-quarter shutdown of its solar wafer production operations. Now, it is bracing for the impact of the coronavirus outbreak as it looks at the year ahead.

“We immediately set up a crisis response task force led by our senior management team and began rolling out initiatives to ensure business continuity including a detailed assessment of our supply chain and logistics, the immediate procurement of critical raw materials, and plans to allow employees return to work, which resulted in uninterrupted production and full utilization during this challenging period,” said Zhang.

Daqo plans to operate its factories at full capacity in the months to come, with an output target of 18,000 MT to 19,000 MT of polysilicon in the first quarter of this year. It expects mono-grade polysilicon products to account for roughly 90% of its sales in the three months to the end of March, Zhang added.

“Toward the end of 2019 we saw the market share for multi-grade polysilicon shift meaningfully towards mono-grade polysilicon,” he concluded, noting that demand for multi-grade polysilicon is falling. “While we are ideally positioned to benefit from this shift towards mono-grade polysilicon, this will adversely impact some of our competitors who produce mostly multi-grade polysilicon.”