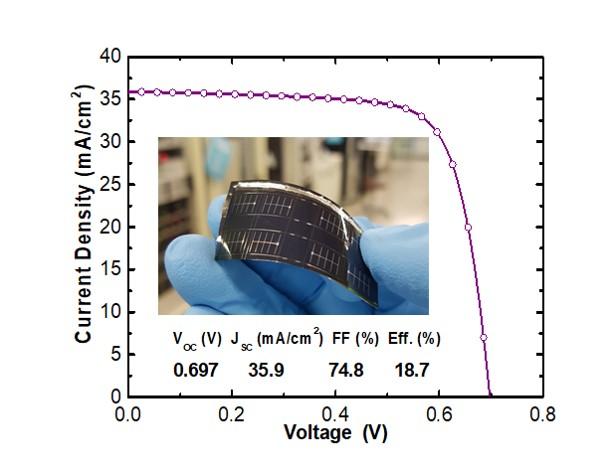

Scientists at the Korea Institute of Energy Research (KIER) have developed a flexible copper, indium, gallium, selenium (CIGS) solar cell for BIPV applications which they say is “ultralight and ultrathin.”

The KIER reported a 20.4% efficiency for the device, although it did not say if the result was confirmed by a third party. This record, the researchers specified, is approaching the world record of 20.8% set for this type of cell by a device manufactured by the Swiss Federal Laboratories for Materials Science and Technology (EMPA) in July last year.

The thin-film cell is based on a flexible plastic substrate for which a conventional CIGS deposition process at around 550 degrees Celsius could not be used. The researchers claim to have used a new low-temperature film formation technology, which has not affected the device’s performance, as usually happens when CIGS cells are grown at a temperature lower than 550 degrees.

Furthermore, the researchers applied alkali-fluorides such as sodium-fluoride and potassium-fluoride to the CIGS absorber layers through an external alkali incorporation technology.

Doping with alkali elements is crucial for achieving high efficiencies in CIGS cells. Although the reason for this increased efficiency has been investigated by many scientists, and various explanations have been given, there is no still no clear definition of their effects in terms of stronger performance.

“This achievement is evaluated as the establishment of a standard process for high efficiency of ultra-light flexible CIGS thin film solar cells,” said the research coordinator, Kihwan Kim. Further details on the cell technology were not provided.

The scientists added they will further investigate how this new process may be used to produce large-area CIGS thin-film solar cells at volume.