From July 20 to 21, the PVRC Seminar was held at the Vienna International Hotel, Suzhou. The conference was sponsored by China Renewable Energy Society and awarded the award of “Top Ten Enterprises in Photovoltaic Product Quality” at the same time. The conference brought together experts in photovoltaic materials, components, brackets, inverters, operation and maintenance, and conducted a comprehensive discussion and technical support on reliability. Dr. Lin Junliang, director of Amarton Key Laboratory, was invited to attend and delivered a keynote speech.

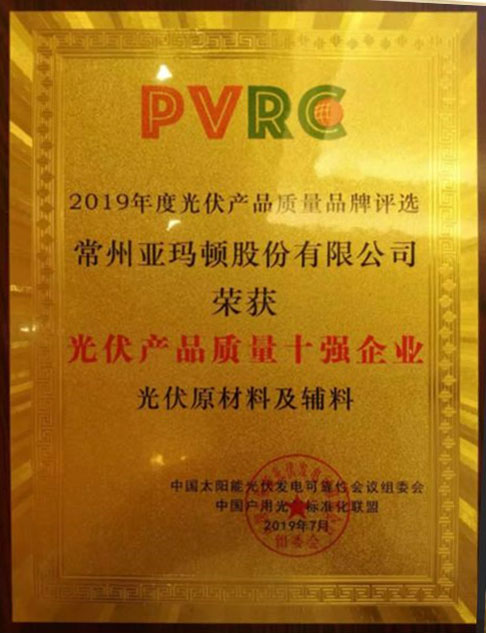

The theme of Dr. Lin Junliang’s speech is “Analysis of Photovoltaic Module Glass and Self-Explosion”. This paper makes a deep analysis of the principle of tempered glass, the difference between material steel and tempered glass, the principle of reinforced glass and the cause of self-explosion. At first, Dr. Lin’s speech analyses the principle and classification of tempered glass and points out that glass breakage is not equal to glass breakage. Self-explosion is defined by the analysis of glass breakage factors, fabrication process and material properties. Internal defect + external micro-stress is defined. Authoritative conclusion is drawn that strengthening glass can increase glass strength and resist external stress, but also increase internal tension stress and increase the risk of self-explosion. Low glass impurities, reduced edge and surface defects and proper control of tempering strength can reduce the self-explosion rate. At the same time, it is pointed out that the tempered glass less than 3.2mm is not easy to self-explode because of its small internal stress. Therefore, the self-exploding risk of the lightweight tempered glass less than or equal to 2mm, which is the main thrust of Amarton, will be minimized. Detailed theoretical and practical solutions made Dr. Lin’s speech recognized and endorsed by experts from all walks of life, and won the honor of “Top Ten Enterprises in Photovoltaic Product Quality” awarded by the conference.

Dr. Lin also showed the participants the newly developed high-transparency and high-reliability anti-reflection coated glass developed by Amarton. With dual AR process, the transmittance can reach 94.2% while improving weatherability, which greatly improves the utilization of positive light. Another new formula of high-reflectivity and high-reliability coated back glass solves the current white on the market. The technical problem of white paint blackening after PID is existed in the back of the paint; Amarton also introduced the latest ultra-light 1.6+1.6mm double glass ribbon frame component. This product is the lightest solution in the double glass ribbon frame at present, and its mechanical load capacity can reach 8100Pa, which has the advantages of ultra-light, ultra-strong and easy installation.

Almaden has been devoting itself to the research and development of photovoltaic glass and ultra-thin double glass components for many years. Its high-transparency and anti-reflection coated glass and high-reflection coated back glass play a leading role in the glass supply in the photovoltaic industry, and continue to maintain the top supplier quality level in the client side. Almaden will continue to enhance its core competitiveness, optimize and upgrade products, actively support customer needs and improve the high-tech value-added products.